Electric vehicle is gradually replacing the traditional petro fueled vehicles, taking up a significant portion of the automobile market. The success of the electric vehicle is attributed to its excellent performance, stability, and versatility, which can only be achieved with the most reliable cable and wire.

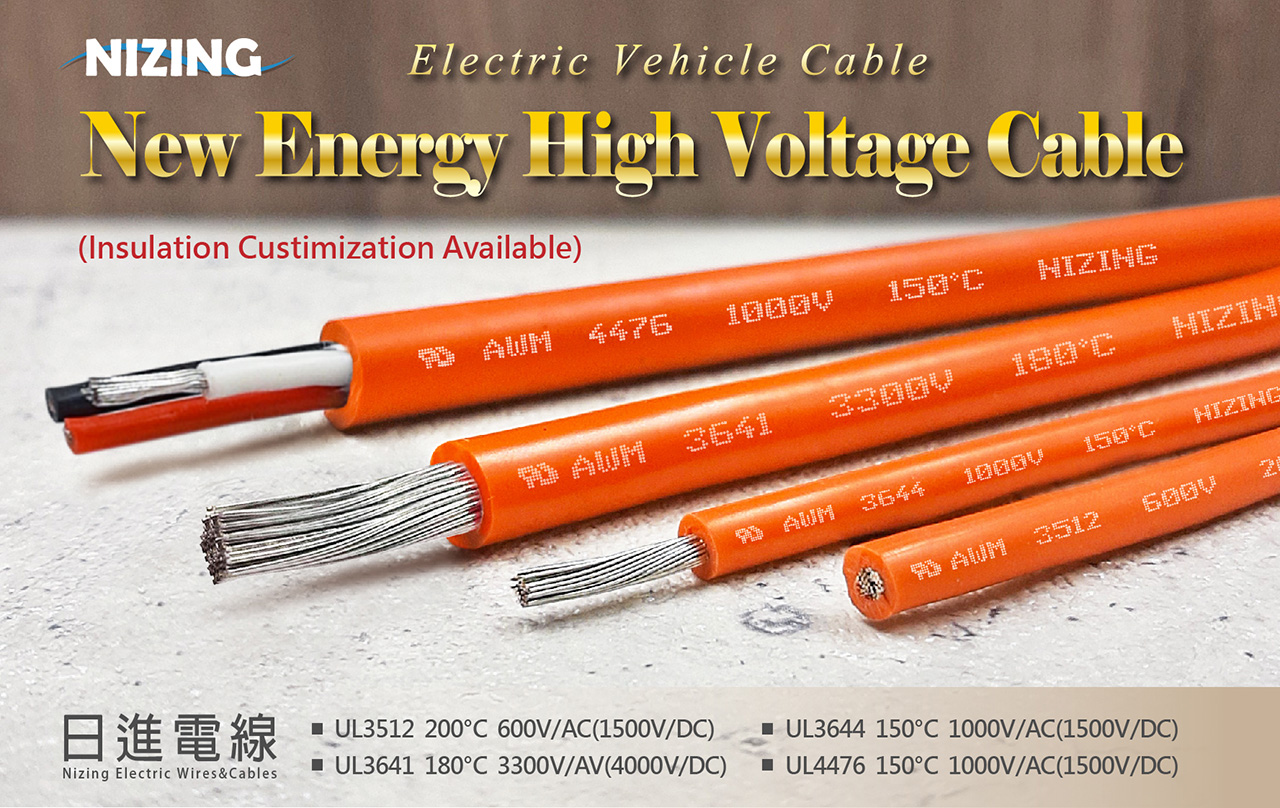

Nizing Electric Wire and Cable provides the best solution for electric vehicles with UL3512 / UL3641 / UL3644 / UL4476, which use silicone rubber as insulation material, and allows customization of inner insulations for wider range of applications.

◆QC/T1037-2016 Cable Restriction:

1. Inspection voltage for AC 900V/DC 1500V is 10KV.

2. Only use bright orange on the outer layer of the wire.

3. Abrasion resistance requires the minimum number of reciprocating movements to be specified as 1000-1500 times.

4. The impregnation time of chemical resistant reagent is changed to 10 seconds. Corrosive gases such as gasoline and diesel will undergo 240H thermal aging after soaking for one hour. Immerse weakly corrosive liquids (such as coolant and glass water) 4 times and heat aging 3000H, then perform winding and insulation test.

5. The self-extinguishing time of the extended combustion test should be less than 30 seconds.

Reference Standard QC/T1037-2016:

Nominal Voltage AC 1000V/DC 1500V and above high voltage cable requirement, test methods, and inspection rules.

(Nominal Voltage that is lower than AC 1000V/DC 1500V belongs to GT/T1838.1-2015)

◆High Voltage Cables for Road Vehicles (QC/T1037-2016) introduction:

Electric vehicle high voltage cable is used in recharge port, battery, ignition, and other components, as carrier of electric current. Due to the harsh and volatile application environment of vehicles, electric vehicle high voltage cable is expected to have great performance.

◆Cables Used In New Energy Vehicle:

◆New Energy Vehicle Cable Spec: